When your continuous operation requires exact rates of product through gravimetric feeding, you could benefit from implementing a loss-in-weight feeder. The key word that classifies the requirement for a loss-in-weight feeder is “continuous.” Extruders and continuous mixers operate, well, continuously. Constantly outputting product is a unique process from batching, which requires special consideration for exact feeding.

What is a loss-in-weight feeder?

Simply put, loss-in-weight feeders are gravimetric feeders that directly measures the material's weight to achieve and maintain a predetermined feed rate. However, the are number of specific considerations and features that should be reviewed when it comes to the specifics of a facility's machinery, which we'll cover more below.

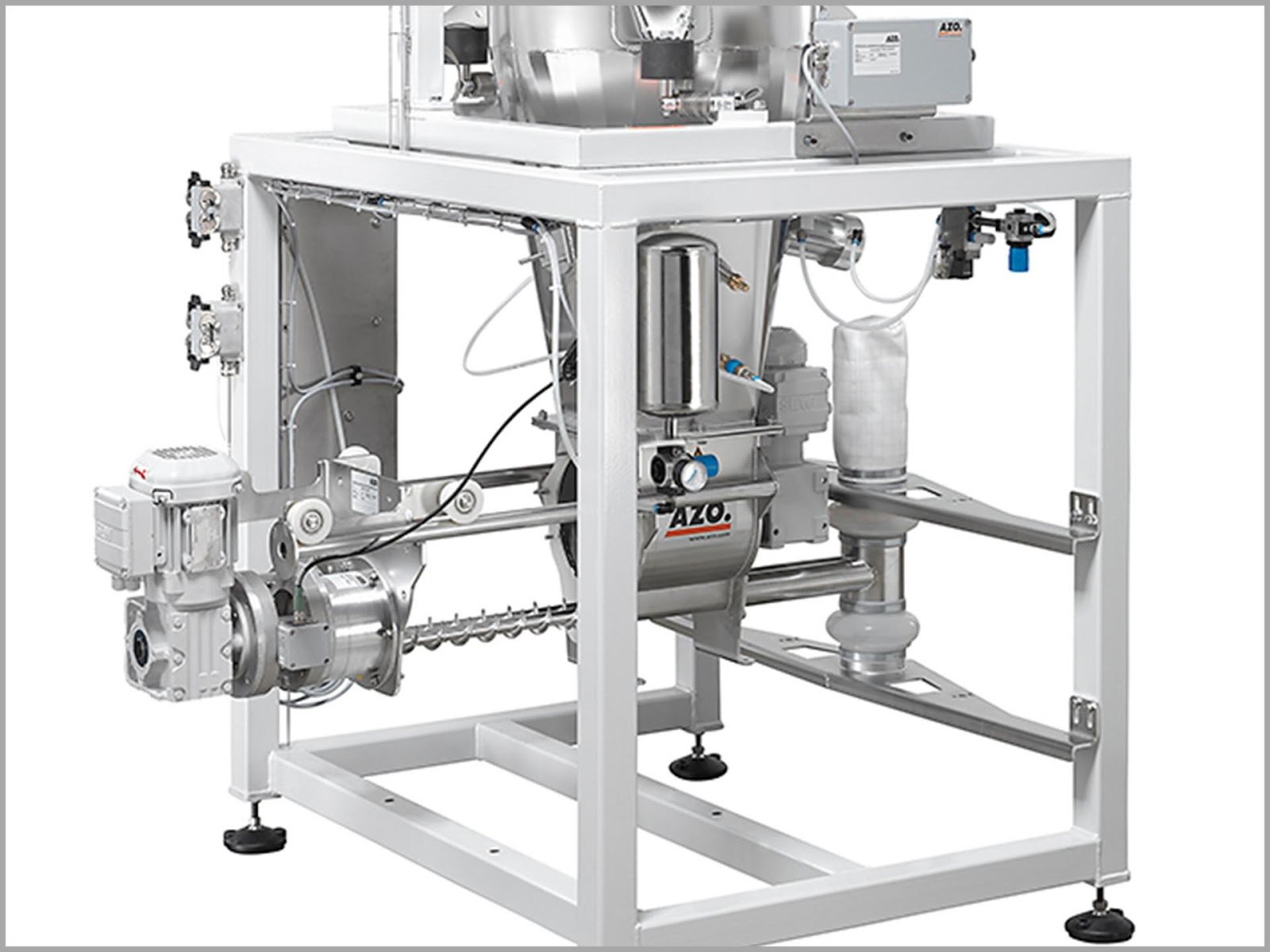

An AZODOS DDW model for gravimetric feeding and continuous dosing of powder products. AZODOS models DV, DW and DDW all use an agitator to discharge powder material from a hopper to feed into the dosing screw.

Capital costs for different types of feeders generally depend on the required feed-rate. When the feed rate requirement is high, the capital cost associated with a loss-in-weight feeder can become prohibitively expensive. Still, if you think in terms of the products dispensed by the feeder, a feeder that isn’t correctly designed will become far more expensive operationally than the capital cost of the feeder itself. This is especially true for loss-in-weight feeders used for continuous processes.

What kind of feeder will serve your operation most effectively? In this post we’ll explain the benefits of loss-in-weight feeders and expand on what these feeders can accomplish:

Gravimetric feeders offer direct measurement of the material being dosed

A fundamental advantage of gravimetric feeders, compared to volumetric feeders, is that gravimetric feeders can make operating adjustments for changes in material density and ambient conditions. Volumetric feeders do not automatically adjust for variations, so there’s no direct measurement of the material being dosed by the feeder.

Continuous production requires a loss-in-weight feeder

Whether you need to feed a dry ingredient or a specific color pigment into a mixer, feeding at a consistent rate can be of critical importance to the desired outcome. This is because the output of an extruder (or any other continuous processor) is produced constantly and must be of consistent quality. While gravimetric feeders can also be used in negative scaling operations, the ability to dose continuously within narrow tolerances is why companies specifically opt for a loss-in-weight feeder for their continuous processes.

Essentially, extruders and continuous mixers need a constant stream of ingredients to produce a consistent stream of finished product. A batch mixer operates in a completely different way. It combines all its ingredients and outputs a single batch of material. Each batch is discrete and quality can be verified to the specific batch.

A continuous extruder or mixer produces a stream of material where it is much harder to perform discrete quality audits. Continuous process recipes (which require materials that are not free-flowing or homogeneous) present a potential quality challenge. A quality loss-in-weight feeder will precisely dose quantities of this type of material more consistently than volumetric feeders.

Loss-in-weight systems can adjust feeding rates based on discharge

The ability to adjust feeding rates based on product discharge is an inherent advantage for loss-in-weight feeders, as compared to gain-in-weight scaling. In a loss-in-weight system, the feeder and the hopper are on weigh cells. As the screw feeder turns and the product is discharged, the weight of the hopper and product decreases. Using special programming, the speed of the screw (and ultimately the discharge rate of the product), can be adjusted for non-homogeneous or poor-flowing material.

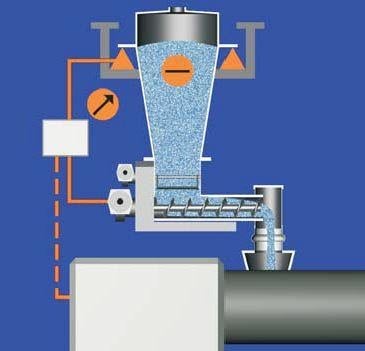

The AZODOS DDW model’s load cells (orange triangles) are located on the feeder and operates through loss-in-weight scaling. The extruder (large grey box) feeds information to the controller (small grey box) which slightly changes the speed of the auger based on how much material is being taken away.

During the refilling of a loss-in-weight feeder, the feeder operates in volumetric mode. This occurs when the product reaches a specific refill level. It is then that the auger continues at a constant speed (not altered by programming). A separate refill hopper dispenses product into the loss-in-weight feeder’s hopper at this point. As soon as the refilling cycle is complete, the scale stabilizes and the feeder resumes gravimetric feeding.

Applications with lower-feed rates benefit from loss-in-weight feeders

Though they generally carry a higher capital cost, it’s essential to remember that loss-in-weight feeders handle lower feed-rates more effectively. Types of material also play a large role in determining whether to utilize a loss-in-weight feeder as well. Typically, a loss-in-weight feeder can handle a large variety of materials because of its ability to adjust the speed of its discharge screw based on the material exiting the storage hopper.

If you have any questions about the AZODOS feeder models or their compatibility with gain-in-weight versus loss-in-weight scaling, contact a dedicated AZO sales associate. You can also check out our blog for more tips on pneumatic conveying and ingredient automation.