Reliable & Continuous Sampling with AZO

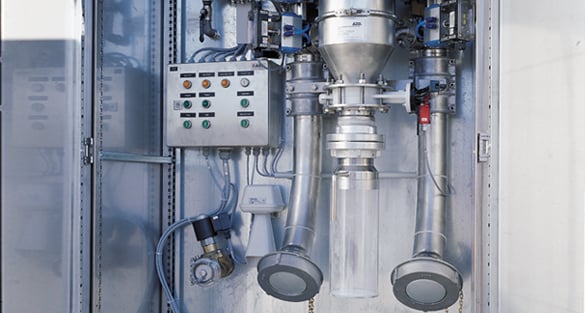

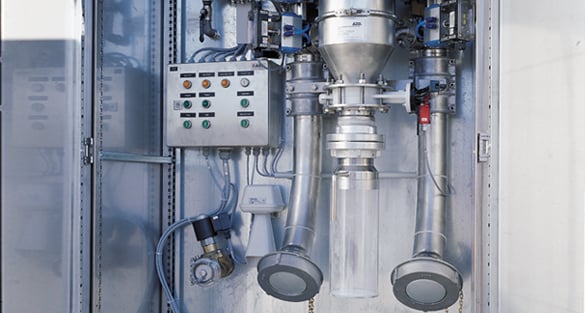

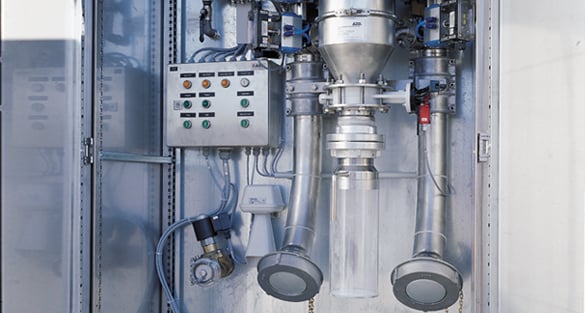

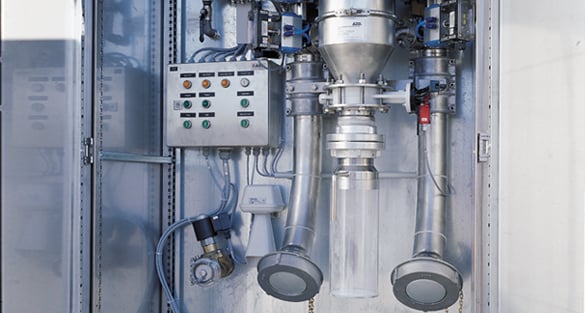

AZO’s sampling unit type PRS is used for the removal of samples from a product that is passing through droptubes or a gravity-fed hopper. The screw shaft inclination and drive can be adjusted to suit sampling capacity needs.

The Benefits You Can Expect

The sampling unit type PRS consists of a screw housing, a screw, the connection flange, and a transparent collection hopper for the samples. Designed for flexibility, the unit is available with pneumatic drive, electric drive, and manual drive options. With regards to installation within a droptube or a hopper, a tri-clamp connection or a flange can be used.

Other advantages of the sampling unit type PRS include:

- A compact design that doesn’t take up unnecessary space

- An easy-to-clean design that suits every operational case

- A quickly mountable design that gets you up and running fast

How AZO's Sampling Unit Type PRS Works

The corresponding control unit determines whether sampling is random or continuous. Based on defined requirements, a pneumatic, electric, or manual turning of the screw removes a certain quantity of the passing product and transports it to the transparent collection hopper. After sampling is complete, the collection hopper that houses the sample is removed via quick-acting clamps and closed with a cover.

The closed hopper can be brought back to the lab. It’s recommended that a new, clean hopper is added to the system immediately to keep the system closed and help prevent contamination.