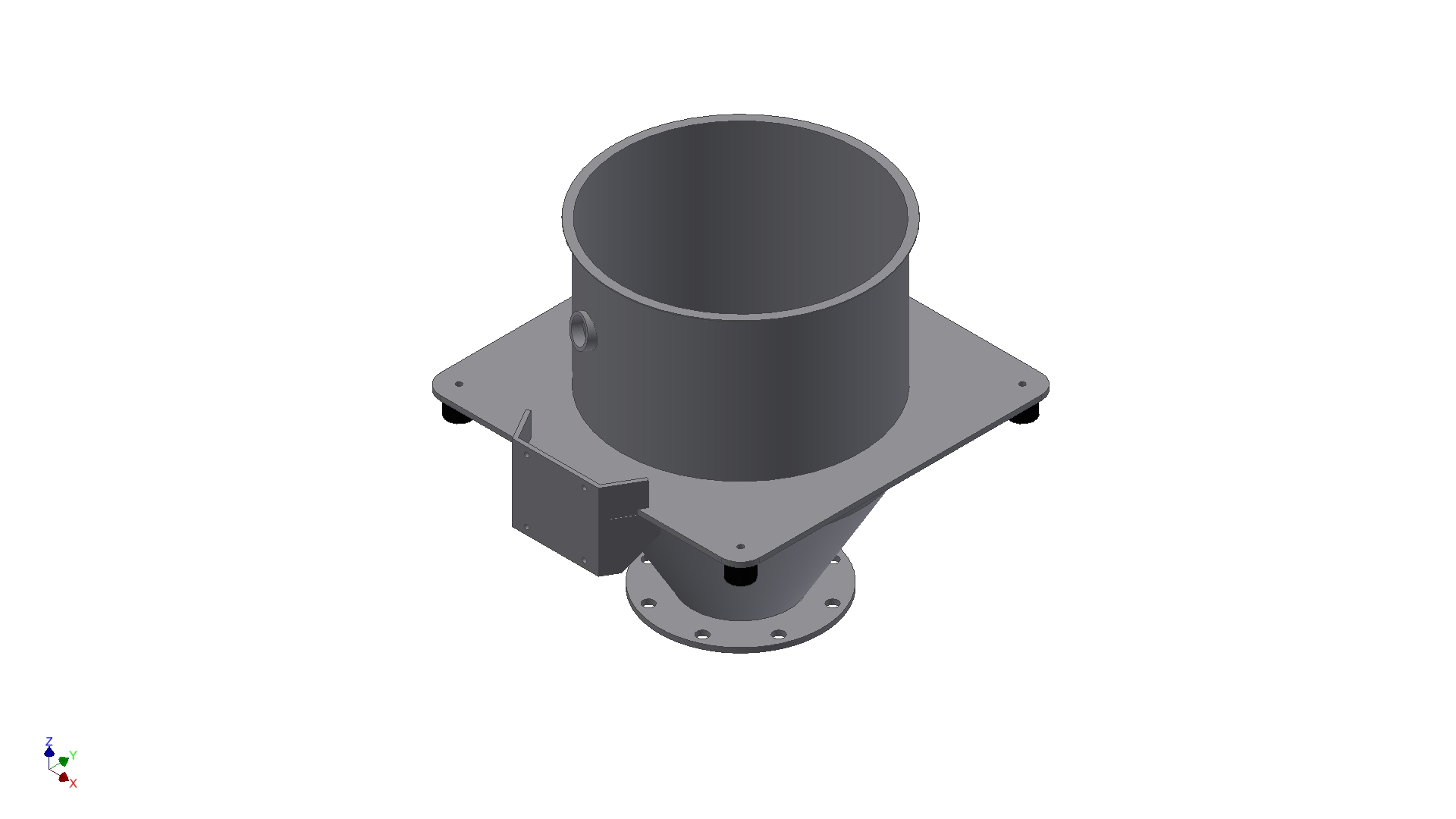

The AZO Model A Low Height Modular Big Bag Unloader for Non-Free-Flowing Ingredients is configured for facilities with lower headroom that are handling especially difficult, non-free-flowing ingredients.

Made of painted steel with a galvanized I-beam and electric chain hoist, the Model A super sack handling system allows for bags to be hung by a single operator, as well as easy bag adjustments to facilitate flow and complete emptying. It has a rated capacity of up to two tons.

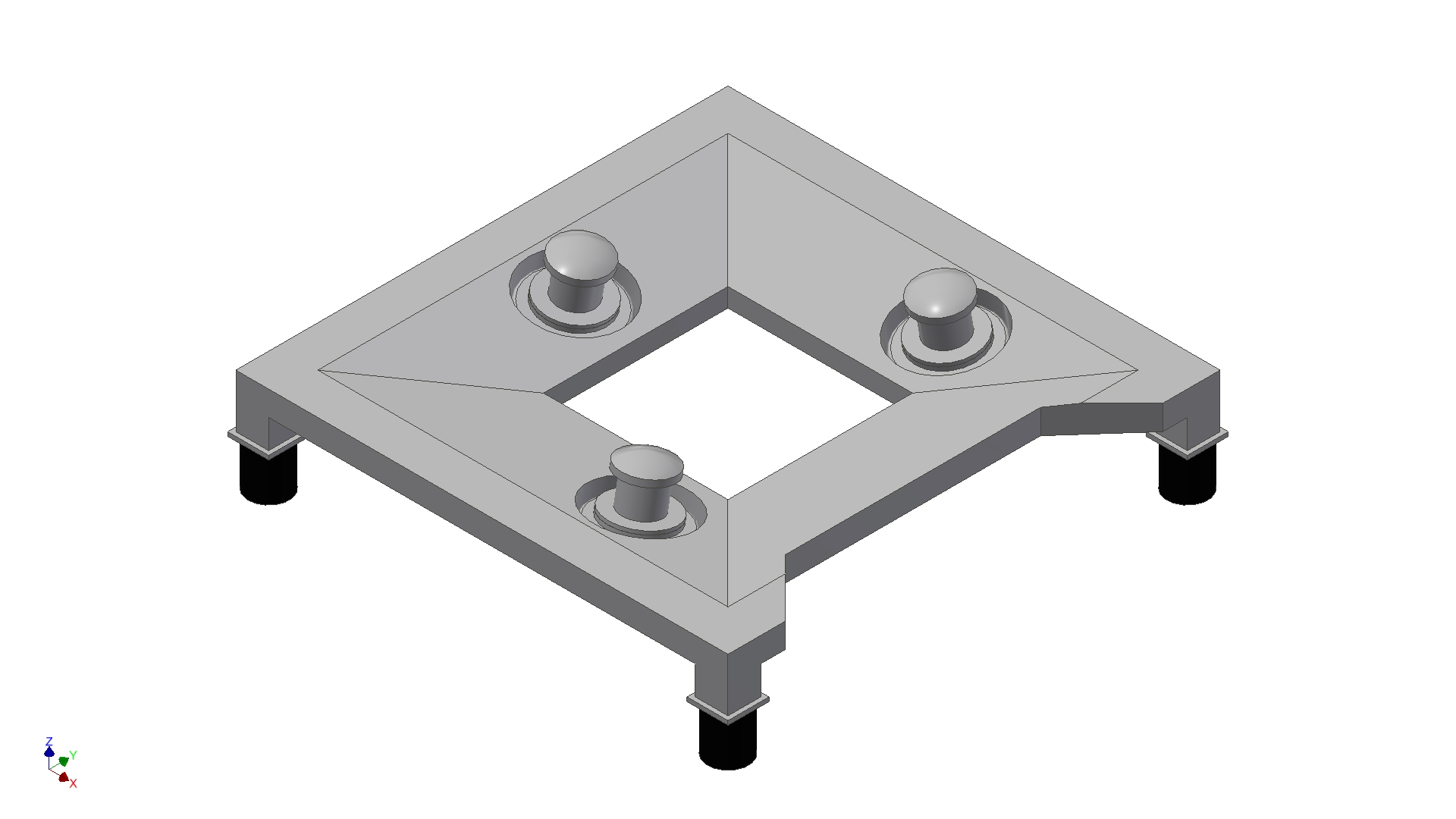

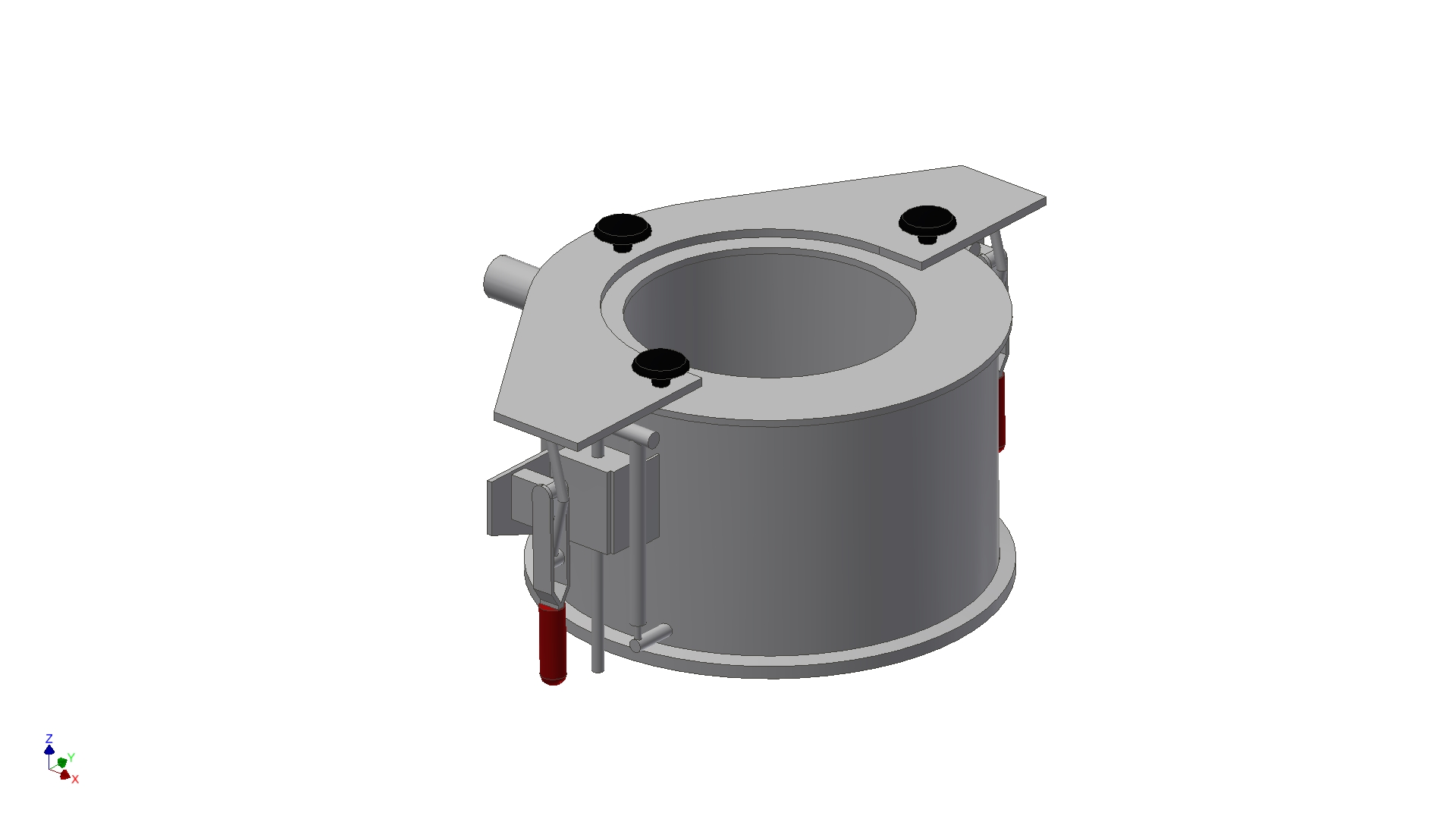

The Model A features both an electronic vibrating feeding hopper with 3.5 cubic feet of storage space, and a safety support platform with massage pads for optimal discharge of poor-flowing ingredients. The connection system helps control dust and contamination.

Our German-engineered modular Big Bag Unloaders are flexible and let your operation quickly react to changing production conditions with minimal or no additional costs.

Request a quote or more info on Big Bag Unloader models below.